銅鎳CuNi10(B10)

| 標準化: | 數字符號: | |

| GB/T9460-2008 | SCu7061 | |

| BS EN ISO24373:2009 | 銅鎳10 | |

| 從 1733 | SG-CuNi10Fe | |

| BS 化學成分: | % | |

| 含銅 | 巴爾. | |

| 錳 | 0.50-1.50 | |

| 鐵 | 0.50-2.00 | |

| 和 | 最大限度 0.20 | |

| 包括公司 | 9.00-11.00 | |

| 磷 | 最大限度 0.02 | |

| 鉛 | 最大限度 0.02 | |

| Ti | 0.10-0.50 | |

| C | 最大限度 0.05 | |

| S | 最大限度 0.02 | |

| 其他總計 | 最大限度 0.40 | |

| 材料物理性能: | ||

| 密度 | 公斤/米^3 | 8.9 |

| 熔化範圍 | ℃ | 1100-1145 |

| 導熱係數 | 瓦/米·K | 30 |

| 電導率 | 小米/毫米^2 | 2.8-3.2 |

| 熱膨脹係數 | 10^-6/K(20-300℃) | 17.0 |

| 焊縫金屬標準值: | ||

| 伸長 | % | 34 |

| 抗拉強度 | 牛/毫米^2 | 300 |

| 缺口棒衝擊工作 | J | 190 |

| 布氏硬度 | HB 2.5/62.5 | 80 |

| 應用領域: | ||

| Used for welding of wrought to themselves or to each other.These filler metals also are used for welding the clad side of copper nickel clad steel.Preheating gernerally is not necessary.Welding is done in all positions.The arc should be kept as short as possible to assure adequate shielding gas coverage and thus minimize porosity.It may be used for surfacing applications where high resistance to corrosion,erosion is required. | ||

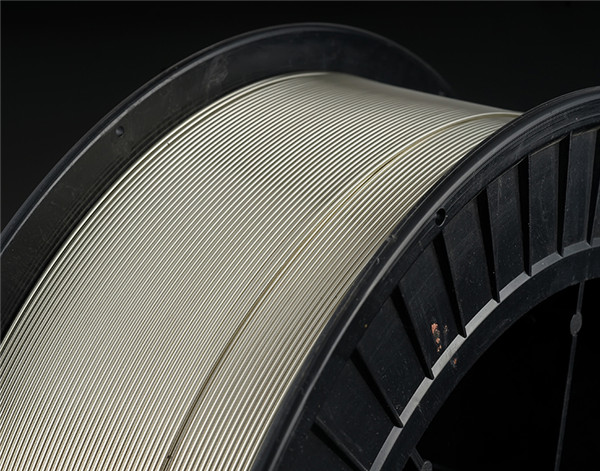

| 化妝品: | ||

| 直徑:1.00 – 1.20 – 1.60 -2.40 | ||

| 線軸:D300 | ||

| 棒:1.60 – 9.6 毫米× 914/1000 毫米 | ||

| 根據要求進一步化妝. | ||

BS EN ISO24373:2009 銅鎳10

留言