鎳鋁青銅(6327)

| 標準化: | 數字符號: | |

| GB/T9460-2008 | SCu6327 | |

| BS EN ISO24373:2009 | CuAl8Ni2Fe2Mn2 | |

| BS 化學成分: | % | |

| 含銅 | 巴爾. | |

| 鋅 | 最大限度 0.20 | |

| 錳 | 0.50-2.50 | |

| 鐵 | 0.50-2.50 | |

| 和 | 最大限度 0.20 | |

| 在 incl.co 中 | 0.50-3.00 | |

| 鋁 | 7.00-9.50 | |

| 鉛 | 最大限度 0.02 | |

| 其他總計 | 最大限度 0.40 | |

| 材料物理性能: | ||

| 密度 | 公斤/米^3 | 7.5 |

| 熔化範圍 | ℃ | 1030-1050 |

| 導熱係數 | 瓦/米·K | 50 |

| 電導率 | 小米/毫米^2 | 4.5-5.5 |

| 熱膨脹係數 | 10^-6/K(20-300℃) | 17.0 |

| 焊縫金屬標準值: | ||

| 伸長 | % | 30 |

| 抗拉強度 | 牛/毫米^2 | 530 |

| 缺口棒衝擊工作 | J | 70 |

| 布氏硬度 | HB 2.5/62.5 | 150 |

| 應用領域: | ||

| 特別適用於銅鋁鎳材料以及鋼和銅鋁合金的連接。鋁青銅的連接和堆焊,鋁塗層鋼,機械製造中的灰口鑄鐵,化學工業和造船業。提高耐磨性和耐磨性。對海水有很好的耐腐蝕性。鋁青銅或特種黃銅合金耐腐蝕管道的連接。應用領域,例如船舶螺旋槳的堆焊。用於鋼材的多層焊接,推薦使用脈衝電弧焊. | ||

| 化妝品: | ||

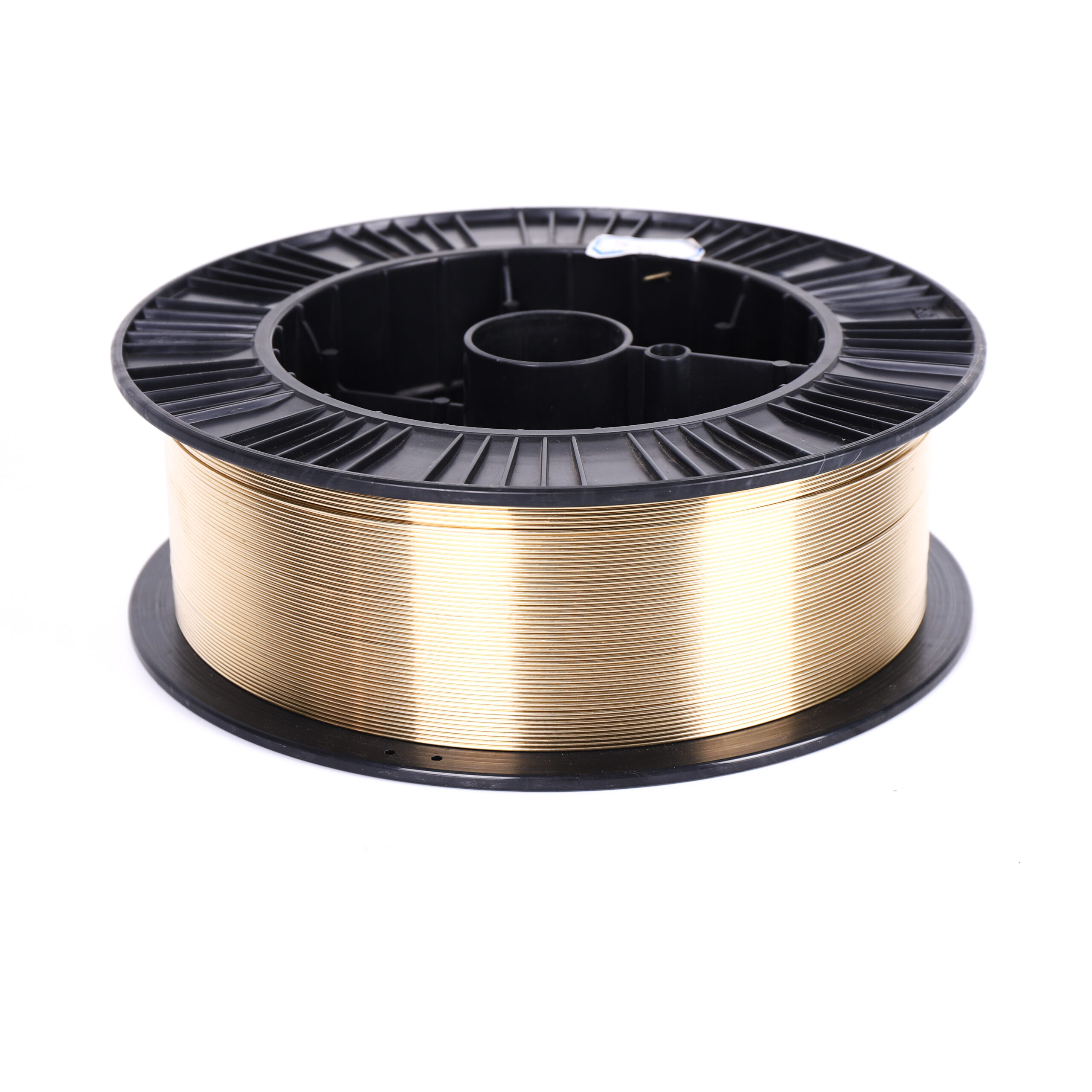

| 直徑:0.64 – 0.80 – 1.00 – 1.20 – 1.60 -2.40 | ||

| 線軸:D100、D200、D300、D760、K300、KS300 | ||

| 棒:1.60 – 9.6 毫米× 914/1000 毫米 | ||

| 根據要求進一步化妝. | ||

BS EN ISO24373 CuAl8Ni2Fe2Mn2

留言