Silizio brontzea

| Normalizazioa: | Zenbakizko Sinboloa: | |

| GB/T9460-2008 | SCu6560 | |

| AWS A5.7:2007 | ERCuSi-A | |

| BS EN ISO24373:2009 | CuSi3Mn1 | |

| HANDIK 1733 | SG-CuSi3 | |

| AWS Chemical Composition: | % | |

| Cu incl.ag | bal. | |

| Zn | 1.00 | |

| Sn | 1.00 | |

| Mn | 1.50 | |

| Fe | 0.50 | |

| Eta | 2.80-4.00 | |

| Al | 0.01 | |

| Pb | 0.02 | |

| Besteak guztira | 0.50 | |

| Materialen propietate fisikoak: | ||

| Dentsitatea | Kg/m^3 | 3.5 |

| Urtze-tartea | ℃ | 965-1030 |

| Eroankortasun termikoa | W/m.K | 35 |

| Eroankortasun elektrikoa | S.m/mm^2 | 3.5-4.0 |

| Dilatazio termikoaren koefizientea | 10^-6/K(20-300℃) | 18.1 |

| Soldadura-metalaren balio estandarrak: | ||

| Luzapena | % | 40 |

| Trakzio erresistentzia | N/mm^2 | 345 |

| Koska-barrako inpaktu lana | J | 55 |

| Brinell gogortasuna | HB 2.5/62.5 | 80 |

| Aplikazioak: | ||

| Joining and overlay welding of copper zinc alloys,low copper materials,also for an excellent wear resisting overlay welding on low and unalloyed steel as well as cast iron.For MIG overlay welding of large work pieces preheating is recommended.For multilayer welding on steels,pulsed arc welding is recommended.Appropriate for MIG brazing of zinc coated sheets. | ||

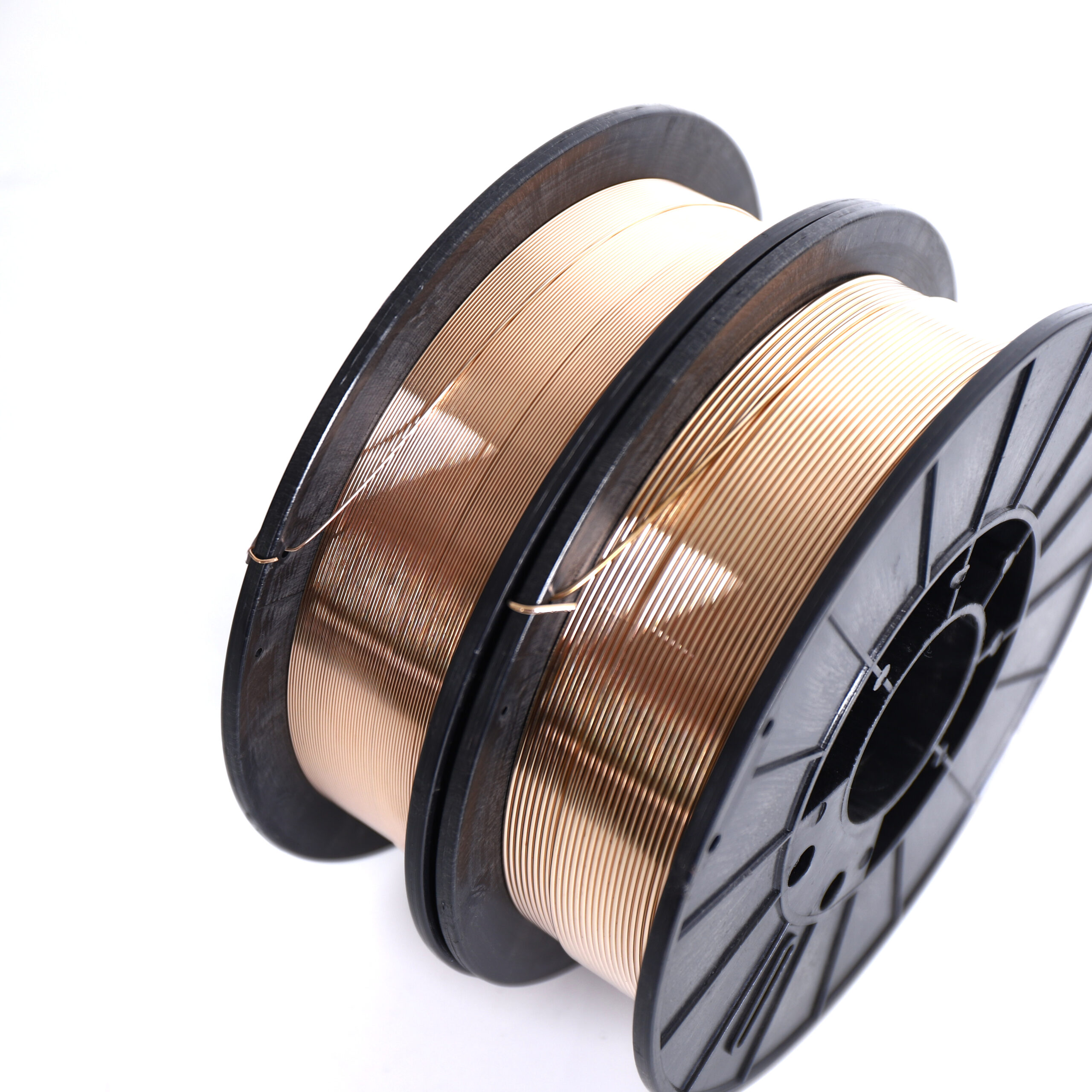

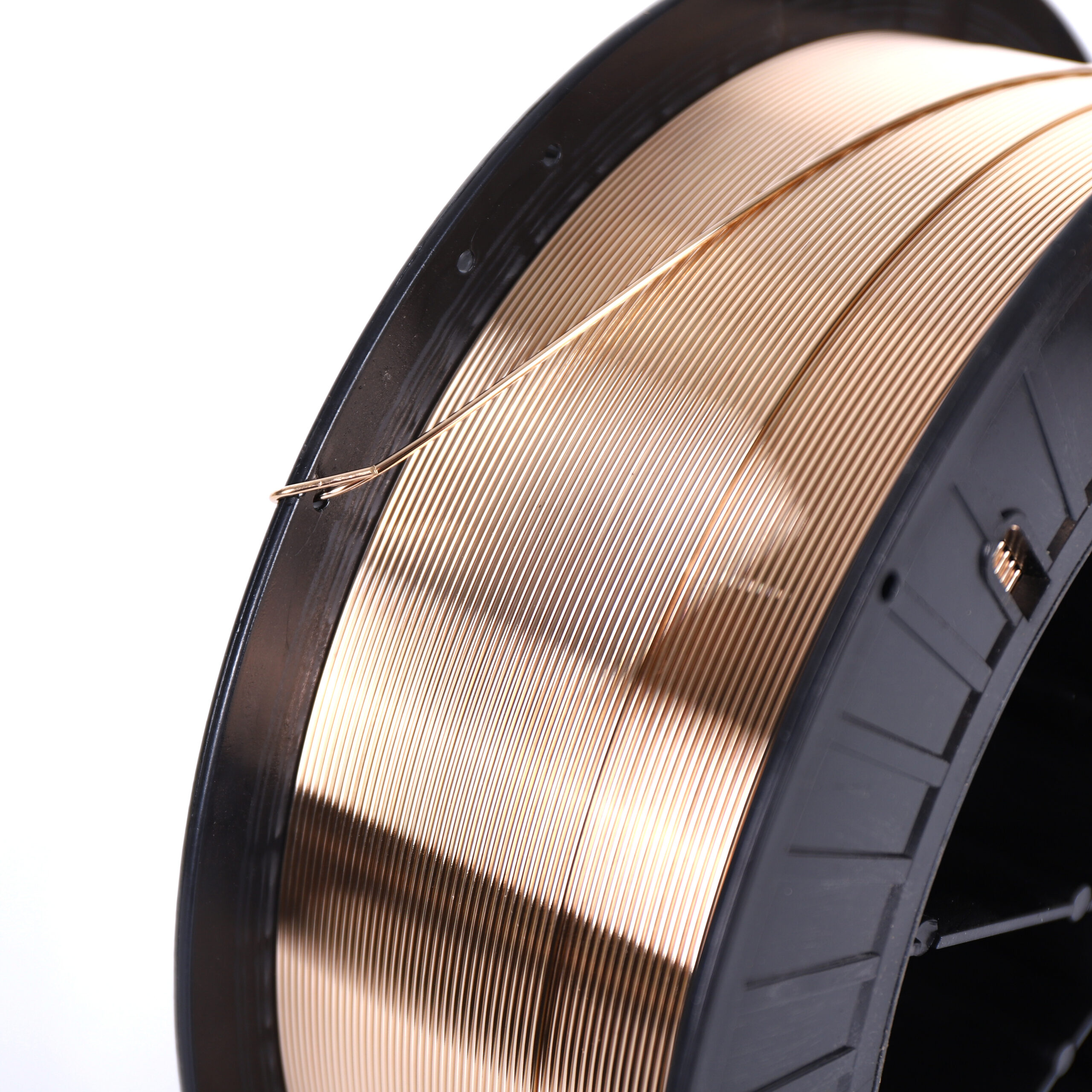

| Makillatu: | ||

| Diametroa:0.64 – 0.80 – 1.00 – 1.20 – 1.60 -2.40 | ||

| Bobinak:D100,D200,D300,D760,K300,KS300 | ||

| Hagaxkak:1.60 – 9.6 mm x 914/1000 mm | ||

| Electrodes available. | ||

| Makillaje gehiago eskatuz gero. | ||

Utzi zure mezua