Nikel-aluminio brontzea(6327)

| Normalizazioa: | Zenbakizko Sinboloa: | |

| GB/T9460-2008 | SCu6327 | |

| BS EN ISO24373:2009 | CuAl8Ni2Fe2Mn2 | |

| BS Konposizio Kimikoa: | % | |

| Cu incl.ag | bal. | |

| Zn | gehienez 0.20 | |

| Mn | 0.50-2.50 | |

| Fe | 0.50-2.50 | |

| Eta | gehienez 0.20 | |

| Ni incl.co | 0.50-3.00 | |

| Al | 7.00-9.50 | |

| Pb | gehienez 0.02 | |

| Besteak guztira | gehienez 0.40 | |

| Materialen propietate fisikoak: | ||

| Dentsitatea | Kg/m^3 | 7.5 |

| Urtze-tartea | ℃ | 1030-1050 |

| Eroankortasun termikoa | W/m.K | 50 |

| Eroankortasun elektrikoa | S.m/mm^2 | 4.5-5.5 |

| Dilatazio termikoaren koefizientea | 10^-6/K(20-300℃) | 17.0 |

| Soldadura-metalaren balio estandarrak: | ||

| Luzapena | % | 30 |

| Trakzio erresistentzia | N/mm^2 | 530 |

| Koska-barrako inpaktu lana | J | 70 |

| Brinell gogortasuna | HB 2.5/62.5 | 150 |

| Aplikazioak: | ||

| Particularly suitable for copper aluminium nickel materials and for joining of steel and Cu-Al alloys.Joining and overlay welding of aluminium bronzes,aluminium coated steel,grey cast iron in the machine building,chemical industry and shipbuilding.Increased resistance against wear and abrasion.Very good corrosion resistance against seawater.Joining of corrosion resistant pipes of aluminium bronze or special brass alloys.Fields of appplication,for example overlay welding of ship propellers.For multilayer welding on steels,pulsed arc welding is recommended. | ||

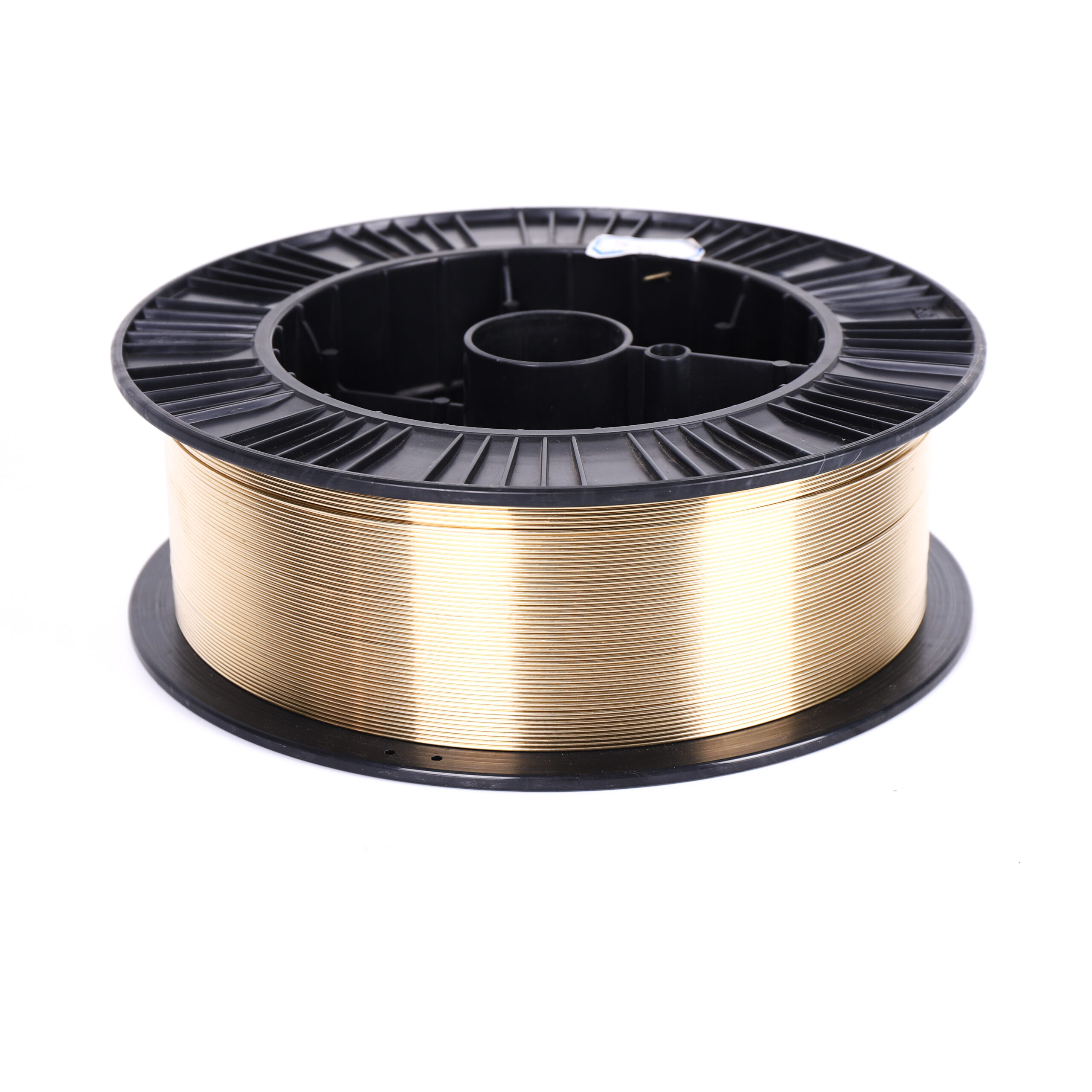

| Makillatu: | ||

| Diametroa:0.64 – 0.80 – 1.00 – 1.20 – 1.60 -2.40 | ||

| Bobinak:D100,D200,D300,D760,K300,KS300 | ||

| Hagaxkak:1.60 – 9.6 mm x 914/1000 mm | ||

| Makillaje gehiago eskatuz gero. | ||

BS EN ISO24373 CuAl8Ni2Fe2Mn2

Utzi zure mezua